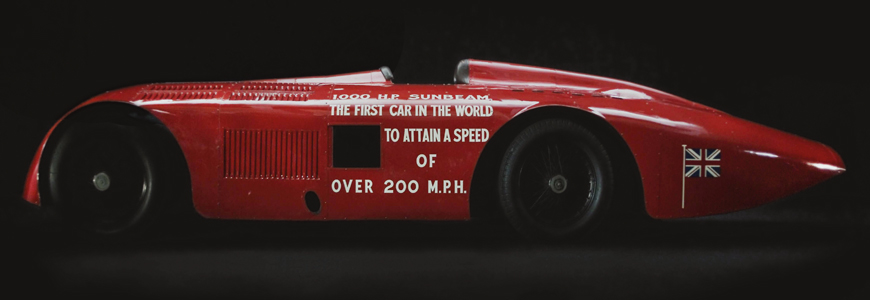

National Motor Museum’s Sunbeam 1000hp project update

Reaching the 90th anniversary of Major Henry Segrave’s 1927 World Land Speed Record on 29 March, there has been a huge amount of interest from across the globe in the National Motor Museum’s Sunbeam 1000hp project. With the aim of preserving this incredible car for future generations, the museum engineers are battling to bring one of its colossal V12 engines back to life in this milestone year.

Work in Progress

Once the rear engine had been lifted from the car’s structure with the aid of a fork-lift truck, the strip-down could begin. The manifolds and carburettors were removed, followed by the long tubular ‘boxes’ that house each of the four cam shafts on the very top of the engine. The two Sunbeam Matabele V12 aero engines were in a bad way after years of inactivity, having suffered due to severe internal corrosion.

Each engine is fitted with four alloy blocks, which locate three cylinders each. These blocks were unbolted from the single crank case and each piston withdrawn from its cylinder. As there are no separate cylinder heads, this is the only way to access and withdraw the valves. Next, with the pistons and connecting rods removed, the huge crankshaft was carefully lifted out of the crank case; this was sent to a specialist for work, along with the connecting rods.

In addition to the known corrosion issues, the engine had suffered due to the decay of its ancient oil, which had turned into a thick, glue-like substance. As a result, perseverance was required from the engineers to make the piston rings relinquish their grip on the pistons. Almost all of the original piston rings were recovered, but a new set will still be created to replace them.

While every component was being fastidiously checked, cleaned and prepared for further service, attention was also turned to the magnetos. Each magneto generates the spark required for ignition and distributes it to the spark plugs, with four magnetos fitted to each Sunbeam Matabele V12 engine. Hooked up to a special test bed, they were found to still be in good health. However, it was deemed prudent to have these components rebuilt by a specialist, to ensure that they are reliable.

As work continues and several components are sent to receive specialist attention, in the build-up towards the final reassembly of the engine, the goal of hearing it run again doesn’t seem so very far off.